Advanced Safety Protection Design Ensures Long-Term Durability of Solar Inverters

As the world accelerates towards clean energy, solar energy keeps gaining momentum as one of the most stable and scalable clean energy sources. At the core of every solar power system that is efficient lies an essential device—the solar inverter. Solar inverters serve the critical function of inverting direct current (DC) output from solar panels to alternating current (AC) that is useable in homes, businesses, and industries. Being their core location, the safety and reliability of solar inverters are crucial. To provide long-term performance and durability, Solar Inverters Manufacturers and Suppliers are integrating enhanced safety protection designs and industrial-grade structural components into their products. Not only do these provide improved safety and reliability but also lower maintenance expenses and consistent power supply throughout the inverter's lifespan.

The Importance of Safety in Solar Inverter Design

Safety is not a characteristic, it's a requirement in solar energy systems. Inverters are subjected to varying weather, voltage spikes, and extended hours of operation, especially in industrial or commercial large-scale installations. Without being equipped with the right safety features, these devices will most certainly overheat, acquire electrical faults, be susceptible to fire, or fail prematurely.

To fight these hazards, contemporary solar inverters now feature a list of advanced protection technologies, including:

● Overvoltage and under-voltage protection

● Short-circuit protection

● Over-temperature shutdown

● Ground fault detection

● Anti-islanding protection

● Arc fault detection

They operate in real time to keep watch over both internal and external conditions, automatically disconnecting the inverter in case of abnormality, and in some instances, alarming the operator for prompt intervention. All these features greatly minimize risks of accident or damage, promoting the overall safety of the solar energy system over the long term.

Industrial-Strength Structural Design: Designed to Last

Even as valuable as safety systems are, they are most effective when complemented by a robust, well-engineered physical design. Industrial-grade solar inverters are built to survive the most hostile environmental and electrical environments. From stand-alone desert installations to coastal installations with high humidity, these units should run faultlessly for years—decades, in most installations.

Key features of industrial-grade inverter construction include:

1. Robust Enclosures

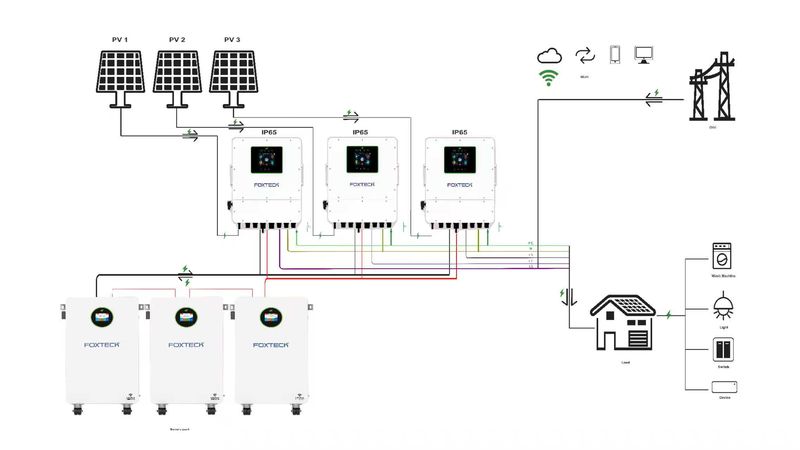

Quality inverters come in IP65 or higher-rated enclosures that are sealed from dust, water, and even tiny particles. They are sealed for outdoor mounting to protect the inner components from the outside world.

2. Corrosion-Resistant Materials

These are commonly used for industrial-grade inverters to keep them from corroding in the long run, especially in marine or high-humidity environments.

3. Thermal Management Systems

Overheating is one of the leading reasons for inverter failure. To combat that, Solar Inverters Manufacturers implement sophisticated cooling systems, such as heat sinks, thermal pads, and smart fans or even liquid cooling in high-power versions. These systems control temperature, minimize component stress, and enhance working life.

4. Modular and Scalable Design

Industrial applications usually demand flexible solutions. Modular inverters enable capacity to be established as and when required and enable repairs and maintenance to be easier. A defective module can be swapped out without shutting down the entire system.

5. Surge Protection and EMC

Industrial inverters must comply with rigorous electromagnetic compatibility (EMC) requirements so that they won't disturb other electric systems. Surge protection devices safeguard against voltage surges caused by lightning strokes or faults within the grid.

Smart Monitoring and Proactive Maintenance

The other important development in inverter design is the incorporation of smart monitoring systems. Through IoT and cloud connectivity, operators are able to monitor inverter performance remotely, receive real-time notifications, and even conduct remote diagnostics. These systems provide invaluable information on temperature, output efficiency, and system health that enable predictive maintenance rather than reactive repair.

Solar Inverters Suppliers with remote monitoring enable users to optimize uptime and extend equipment life. In addition to reducing downtime, this also lowers operational expenses—two essential concerns for industrial users operating with huge solar installations.

Adherence to International Standards of Safety

In order to fulfill the growing demands of safety and reliability, trustworthy Solar Inverters Manufacturers must ensure that their product adheres to global standards like:

● IEC 62109-1 / IEC 62109-2 – Safety of power converters for use in photovoltaic systems

● UL 1741 – Inverter safety for grid-interactive and stand-alone systems

● IEEE 1547 – Standard for interconnection of distributed energy resources

● ISO 9001 & ISO 14001 – Quality and environmental management standards

Conformity to these standards ensures customers that the inverter has been well tested and meets international standards of quality and safety.

Industrial Applications Demand Industrial-Grade Solutions

Whereas home solar inverters may emphasize aesthetics and cost, industrial use cannot compromise on performance and durability. No matter if they are used in a solar farm, commercial rooftop installation, or factory, industrial solar inverters are designed to run 24/7 under harsh conditions.

Solar Inverters Suppliers who have industrial-grade enclosure experience are ideally suited to address this market. They realize the value of heavy-duty enclosures, design scalability, fail-safe performance, and long-term reliability. The investment in a quality inverter not only minimizes the risk of failure but also optimizes return on investment with stable energy production.

Co-operating with the Suitable Supplier

Choosing the correct Solar Inverter Manufacturer or Supplier is crucial. Apart from cost and technical details, customers should also look for the reputation of the supplier, customer care, warranty, and after-sales service. A reliable supplier will provide:

● Detailed product manuals

● Installation and commissioning assistance

● Responsive technical support

● Availability of spare parts

● Tailoring to individual industrial requirements

By allying with experienced manufacturers, industrial consumers can be certain that their investment in solar is safeguarded by stable, dependable, and smart inverter solutions.

Why Foxtech Solar is Different

Where high-performance, safe and quality solar inverter solutions are concerned, Foxtech Solar is the best. With an unfaltering commitment to industrial-grade performance and quality engineering, Foxtech Solar engineers its inverters to satisfy the rigorous demands of contemporary solar installations.

Their offerings boast cutting-edge safety protection mechanisms, intelligent thermal control, and are housed in weatherproof, heavy-duty enclosures. Foxtech Solar works with some of the most seasoned engineers in the business to guarantee that each unit not only meets global safety regulations but also surpasses expectations in long-term durability.

What really distinguishes them is their dedication to customer service. No matter if you are an EPC contractor, solar developer, or energy consultant, Foxtech Solar is an active participant in servicing your project from beginning to end. Their extensive background in industrial solar applications means you receive more than a product—you gain a partner in power.

If you are searching for a reliable Solar Inverters Supplier with a good emphasis on cutting-edge safety and industrial performance, Foxtech Solar is one you can rely on.

Foxtech Solar was founded on the desire to create a solar cleaning energy life for the world – including solar modules, lithium batteries, solar inverter, solar power system.